Finned Tubes

Profins is the largest manufacturer of helical high finned tube in the United Kingdom with the facility to produce in excess of 10,000 metres of quality finned tube per week.

Our ability to draw base tube from our stock of over 1,000 tonnes allows us to react quickly to clients’ demands and to remain competitive with any other producer worldwide. Profins’ finning facility enables numerous fin and tube material and size combinations to be manufactured. This gives us unrivalled flexibility and allows us to react swiftly to emergency orders.

Weekly Production Capacity

Base tube in stock

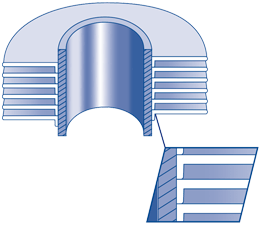

'L' FINNED TUBE

The strip material is subjected to controlled deformation under tension giving the optimum contact pressure of the foot of the fin onto the base tube thus maximising the heat transfer properties.

The foot of the fin considerably enhances the corrosion protection of the base tube.

- MAXIMUM WORKING TEMPERATURE150°C

- ATMOSPHERIC CORROSION RESISTANCE MEDIUM

- MECHANICAL RESISTANCE RESISTANCE LOW

- FIN MATERIALS ALUMINIUM, COPPER

- TUBE MATERIALS ANY THEORETICAL LIMIT

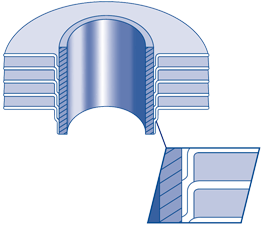

'LL' FINNED TUBE

Manufactured in the same way as the 'L' finned tube type except that the fin foot is overlapped to completely enclose the base tube thereby giving excellent corrosion resistance. This type of finned tube is often used as an alternative to the more expensive extruded type fin in corrosive environments.

- MAXIMUM WORKING TEMPERATURE180°C

- ATMOSPHERIC CORROSION RESISTANCE HIGH

- MECHANICAL RESISTANCE LOW

- FIN MATERIALS ALUMINIUM, COPPER

- TUBE MATERIALS ANY THEORETICAL LIMIT

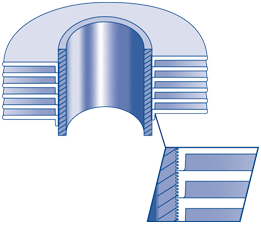

'KL' FINNED TUBE

Manufactured exactly as the 'L' finned tube except that the base tube is knurled before application of the fin foot. After application, the fin foot is knurled into the corresponding knurling on the base tube thereby enhancing the bond between the fin and tube, resulting in improved heat transfer characteristics.

- MAXIMUM WORKING TEMPERATURE260°C

- ATMOSPHERIC CORROSION RESISTANCE MEDIUM

- MECHANICAL RESISTANCE MEDIUM

- FIN MATERIALS ALUMINIUM, COPPER

- TUBE MATERIALS ANY THEORETICAL LIMIT

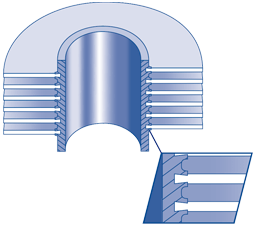

'G' EMBEDDED FINNED TUBE

The fin strip is wound into a machined groove and securely locked into place by back filling with base tube material. This ensures that maximum heat transfer is maintained at high tube metal temperatures.

- MAXIMUM WORKING TEMPERATURE400°C

- ATMOSPHERIC CORROSION RESISTANCE LOW

- MECHANICAL RESISTANCE MEDIUM

- FIN MATERIALS ALUMINIUM, COPPER, CARBON STEEL

- TUBE MATERIALS ANY THEORETICAL LIMIT

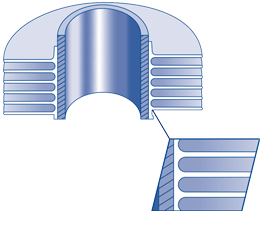

EXTRUDED FINNED TUBE

This fin type is formed from a bi-metallic tube consisting of an aluminium outer tube and an inner tube of almost any material. The fin is formed by rolling material from the outside of the exterior tube to give an integral fin with excellent heat transfer properties and longevity. Extruded fin offers excellent corrosion protection of the base tube.

- MAXIMUM WORKING TEMPERATURE285°C

- ATMOSPHERIC CORROSION RESISTANCE HIGH

- MECHANICAL RESISTANCE HIGH

- FIN MATERIALS ALUMINIUM

- TUBE MATERIALS ANY THEORETICAL LIMIT